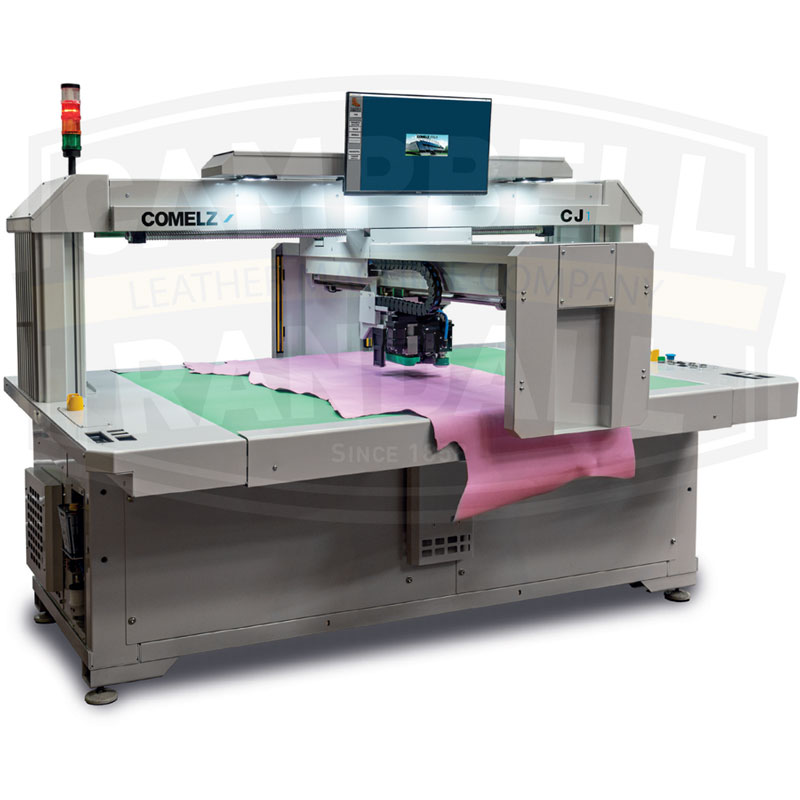

COMELZ CJ Series Fixed Table CNC Cutting Machine with Single Head

Call for Pricing: (936) 539-1400

{{intRating}}| {{ intCurrentReviewCount}} REVIEWS 3395

Or

| Part List | |

|---|---|

| Part | RLM-CLZ-CJ3 |

| Availability | No |

Qty 1-5: Low Inventory - Contact Us to confirm pricing and availability

Request For InformationThe most innovative fixed table CNC cutting machine on the market. The COMELZ CJ Series automatic cutting system features high performance CAD/CAM cutting with an open table format, innovative bridge frame construction, and improved CE + TUV safety features.

SUSPENDED BRIDGE: The arm that supports the cutting head moves on linear guides applied to a suspended bridge and not to the work table. Therefore, the material the needs to be cut (leather, textile, or other non-rigid materials) can freely extend beyond the edges of the table without the need to be inserted into cradles or small slots.

UNPRECEDENTED SAFETY FEATURES: Fixed table machine where the operator must work next to the cutting devices can create safety relates issues. Comelz developed the first machine with triple protection from the cutting devices (two pairs of safety light curtains, a shifting cover and two pivoting plates on the front and the back of the arm.

PROJECTION: CJ machines can be equipped with regular LCD projectors or with laser projectors (optional). In both case the projectors are placed on the back of the suspended bridge and therefore the operator body does not interfere with the projection. The projection angle maximizes the light intensity of the projection.

FEATURES:

The machine, even in the standard configuration, has most of the same state-of-the-art features available on Comelz top of the line machines:

- 7 tool cutting head (high frequency pneumatic knife, 4 independent punching units, pen, pin punch)

- High precision endless screws (in place of more economical drive belts or rack-and-pinion systems)

- Micro-partialization system for the vacuum of the cutting are

- Vacuum pump (up to 17.5KW) enclosed in a cooled and sound-proofed area inside the machine

- Electronic lubrification system for the cutting unit

- Isolation transformer for protection against most electric power supply issues

- Comelz machine control software and automatic nesting function are highly regarded for being user friendly and intuitive

- CJ1 Work area 1600 x 1000 mm

- CJ3 Work area 3000 x 1000 mm

- Cutting speed 60 m/min

- Maximum punching frequency 600 p/min

- Air supply 150 NL/min a 6 bar

- Maximum power consumption 20 KVA

OPTIONS:

- LIGHTS: The suspended bride is the perfect place to support the optional LED lightning system. The light intensity can be adjusted manually by the operator or automatically by the software based on the particular operation that is done in a particular area of the work table (part placing, cutting, part collection).

- PROJECTION: CJ machines can be equipped with regular LCD projectors or with laser projectors (optional). In both case the projectors are placed on the back of the suspended bridge and therefore the operator body does not interfere with the projection. The projection angle maximizes the light intensity of the projection.

- VISION SYSTEM: Thanks to the Comelz advanced multicamera Vision system, it is possible to perform a: vision-controlled cutting (textile with patterns/logos), final trimming operations and leather digitalization for online automatic nesting.

- POWER SUPPLY: 400V - 50/60 Hz - 3 phase standard. Optional transformer for 220V - 50/60 Hz - 3 phase on request

- COMELZ CAD/CAM system: Powerful design software for footwear or leather goods.

Error

- {{ error }}